Recent Blog Posts

-

10/10/2025VIDEO: How often does a Survival Sock get knit at NEAFP?

-

09/12/2025NEW Downloadable Content: Alpaca Dinner Time Coloring Page

-

08/15/2025Reviews: What People are Saying About Bouclé Lined Mittens!

-

08/15/2025Get Ready for NAFD! 5 Ways to make the most out of your Open House!

-

06/26/2025NEW Downloadable Content: Find the Difference Activity Page

-

04/25/2025VIDEO: Take a Virtual Tour of our Mill!

-

01/17/2025Reviews: What People are Saying About The Survival Sock!

-

09/13/2024Download A Free Handwear Informational Print Out!

Alpaca Coloring Pages

- Happy Memorial Day 2024: Alpaca's Grazing

- Winter #1: Build a Snowman Activity

- Winter #2: Extreme Sports

- Valentine's Day: Alpaca Wedding

- St. Patrick's Day: Leprechaun

- Spring: April Showers

- Summer: Beach Day

- 4th of July: Colonial Alpacas

- Summer: Farmer's Market

- Fall: Apple Picking

- Halloween #1: Costume Contest

- Halloween #2: Spooktacular Halloween

- Thanksgiving #1: Giving Thanks Activity

- Thanksgiving #2: Pilgrim Alpacas

- Christmas #1: Deck the Halls

- Christmas #2: Santa's Workshop

Alpaca Fact Series

Business Resources

- Article: Email is still a MUST DO for all Alpaca Farms

- Article: Off the Beaten Path Event Ideas on the Alpaca Farm

- Download: Sock Photo Download Folder

- Graphics: Shop Small this Holiday Season

- Article: Form Follows Function: Dressing for Fall and Winter 2020

- Graphics: Sock and Handwear Comparisons

- Article: A Change in the Seasons: Farms Continue to Adapt into the Busy Harvest Season

- Graphics: How to Support Alpaca Farms

- Graphics: Alpaca Fiber Properties

- Article: Customer Retention: Building Customer Loyalty for your Ecommerce Business

- Article: Harnessing Storytelling to Market Your Business

- Article: The New Normal and a Renewed Support for U.S. Alpaca

- Article: Use Gift Cards to Increase Sales

- Article: Virtual Farm Tours: Bringing People & Alpacas Together in the Virtual World

- Graphics: Get the Most out of your Fiber Harvest

- Graphics: Alpaca Knitter's Yarn Guide

- Article: Mike and Sean's Adventure in Retailing

- Article: Harnessing Holiday Sales Momentum into the New Year

- Graphics: U.S. Alpaca Holiday Gift Guide

- Graphics: Small Business Saturday Resources

- Article: Tools and Topics for Implementing Healthy Soil Agriculture

- Article: Successful Social Media Marketing for Alpaca Farms

- Article: Agritourism on the Alpaca Farm

- Article: Finding Success at Fall and Winter Markets

- Article: Brand Identity & Your Local Community

- Article: Social Media: Alpacas are STILL Seriously Trending

- Article: Let's Get Personal: Expanding your Inventory with Product Personalization

- Article: Part 2: Promoting your Brand Online through Product Styling

- Article: Promoting your Brand Online through Product Styling

- Article: 7 Old School Ways to Spread the Word about your Event

- Article: 5 Ways your Open House can increase Future Sales

- Article: Top Alpaca Related Hashtags to increase your Reach!

- Article: Alpacas are SERIOUSLY Trending

- Article: How to Utilize CO-MARKETING

- Article: Farmers Share their Booths and Tips

- Article: Mobile Payment Survey Results

- Article: Product Photography Do’s and Don'ts

- Article: Driving Business After the Holidays

- Article: Marketing Reflection and Planning

- Article: The Slow Alpaca meets Slow Fashion

- Article: Use Gift Cards to Increase Sales

- Article: The Importance of Being Mobile Friendly

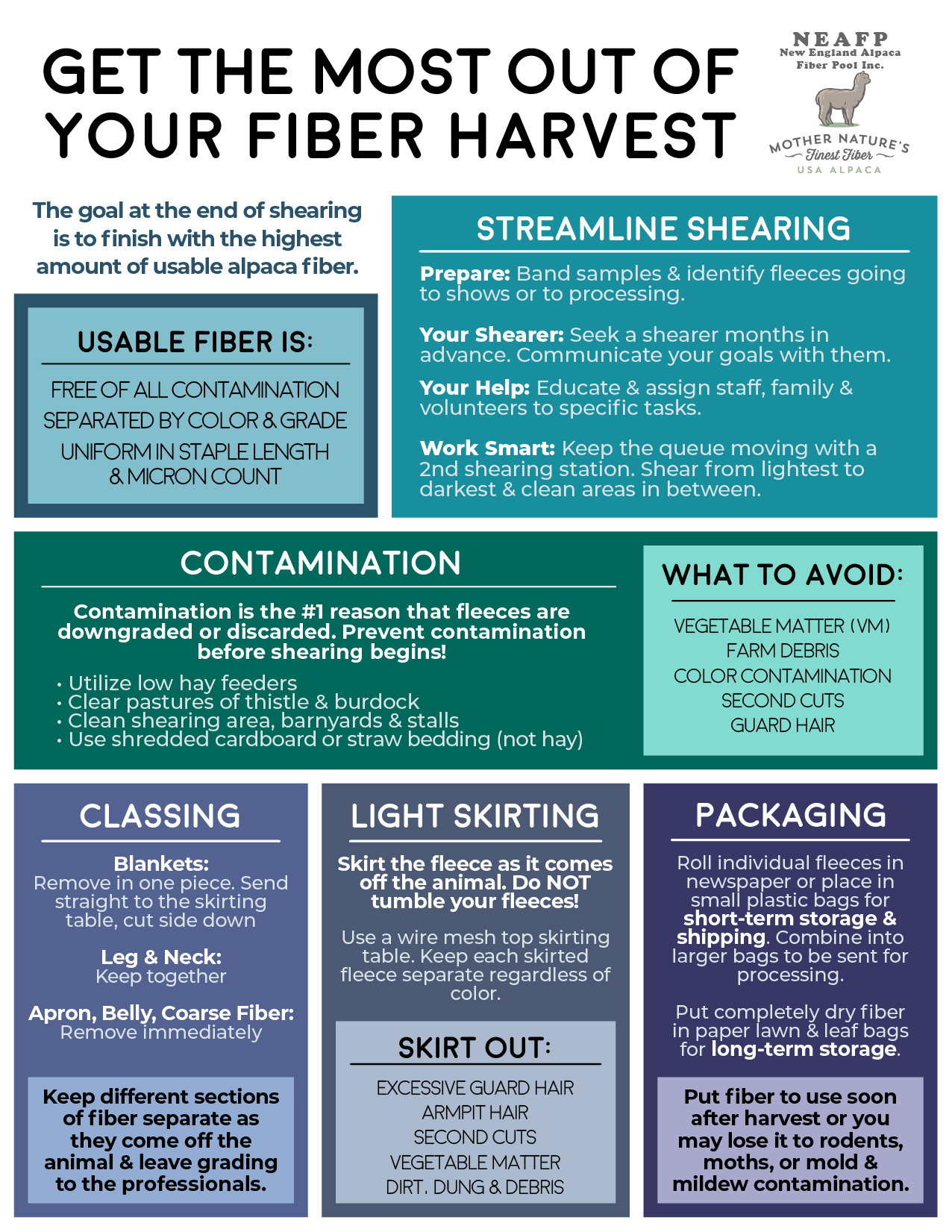

Free Resource: How to get the most out of this year's Fiber Harvest

Get the Most Out of Your Fiber Harvest

We've condensed our Fiber Harvesting Guide into the infographic below, so you can avoid the most common mistakes in alpaca fiber harvesting to ensure you finish with the highest commercially usable clip!

DOWNLOAD A FULL SIZE VERSION HERE:

PDF - JPG

Your Goal:

The goal at the end of shearing is to finish with the highest amount of usable alpaca fiber.

Usable Alpaca Fiber is:

◆ Free of all contamination

◆ Separated by color & grade

◆ Uniform in staple length & micron count

1. Contamination:

Contamination is the #1 reason that fleeces are downgraded or discarded.

Prevent contamination before shearing begins!

◆ Utilize low hay feeders

◆ Clear pastures of thistle & burdock

◆ Clean shearing area, barnyards & stalls

◆ Use shredded cardboard or straw bedding (not hay)

Top Contaminants Include:

◆ Vegetable Matter (VM)

◆ Farm Debris

◆ Color Contamination

◆ Second Cuts

◆ Guard Hair

2. Streamline Shearing:

Prepare: Band samples & identify fleeces going to shows or to processing.

Your Shearer: Seek a shearer months in advance. Communicate your goals with them.

Your Help: Educate & assign staff, family & volunteers to specific tasks.

Work Smart: Keep the queue moving with a 2nd shearing station.

Shear from lightest to darkest & clean areas in between.

3. Classing

Blankets: Remove in one piece. Send straight to the skirting table, cut side down

Leg & Neck: Keep together

Apron, Belly, Coarse Fiber: Remove immediately

Keep different sections of fiber separate as they come off the animal & leave grading to the professionals.

4. Light Skirting

Skirt the fleece as it comes off the animal. Do NOT tumble your fleeces!

Use a wire mesh top skirting table. Keep each skirted fleece separate regardless of color.

Be Sure to Skirt Out:

◆ Excessive Guard Hair

◆ Armpit Hair

◆ Second Cuts

◆ Vegetable Matter

◆ Dirt, Dung & Debris

5. Packaging

Roll individual fleeces in newspaper or place in small plastic bags for short-term storage & shipping.

Combine into larger bags to be sent for processing.

Put completely dry fiber in paper lawn & leaf bags for long-term storage.

Put fiber to use soon after harvest or you may lose it to rodents, moths, or mold & mildew contamination.